Tighten A Chainsaw Chain: Avoid Over-Tight Or Loose (11 Steps)

A lot of chainsaw accidents have occurred due to the chain jumping off the guide bar while in operation and hurting those around. But it’s also dangerous to over-tighten your chain as the force being applied to the chain while in operation could make it snap and hurt people around. Check out the 11-step to tighten chain tension in detail.

The Author

The chainsaw has very high efficiency, and you can use it with little or no stress to cut and slice trees.

The efficiency of the chainsaw would reduce if the chain of the chainsaw is too tight or too loose.

The user will find it more difficult to cut.

As a handyman or a woodworker, you need to maintain the efficiency of your chainsaw.

After prolonged use, the tension in the chains would deteriorate; hence, the chains on your chainsaw will become loose and would sag.

No matter how powerful or easy-to-handle chainsaw you buy, without proper chain tension, you would not get the best cutting performance from it.

Every user is advised to be alert and watchful about this because the situation is always very dangerous.

A lot of chainsaw accidents have occurred due to the chain jumping off the guide bar while in operation and hurting those around.

But it’s also dangerous to over-tighten your chain as the force being applied to the chain while in operation could make it snap and hurt people around.

This is why it’s important to check your chainsaws regularly and rectify any of these anomalies once spotted.

In this article, you will not only learn how to tighten a chainsaw, but our main goal is to give you a better understanding of the proper amount of tension required for your tool according to the work you are doing with it.

11 Steps on how to tighten screws

How to Check the Proper Tension?

To check whether is it necessary to change your chainsaw tension or not, all you need to is to just pull away the chain from the guide bar a little.

If the drive link remains engaged, then you don’t need to worry about the tension and you are ready to go.

If the reverse is the case, then you should start thinking of how to adjust the tension.

There are basically two types of tension which can occur in Chainsaw Chains:

- Good tension

- Bad tension

Good Tension

It happens just because of slight and little loose on the chainsaw guide bar.

The point to note is you must have to tighten the chain to properly pull.

Bad Tension

This occurs when drive links of the chainsaw chain get aside from their real working place.

In this case, there is a time to tighten the chain properly.

Otherwise, you may face a serious risk of getting injured.

So, to prevent the chain from losing tension, the following steps should be kept in mind.

There are Nuts on the sidebar Panel, Lose those Nuts

By going out through this step will provide the chain enough room and space to get settled on the right place.

Tighten the Tensioning Screw

If the screw becomes tight then it will prove immense assistance in tightening of the chain and vice versa.

Screws on Guide Bar Side Panel should be tightened

This will tighten the chain as the screws get tighter.

Screws play very pivotal role and are widely regarded as the most important part of the Chainsaw Chain

This all took even less than a minute but it can provide ease and facilitate us with the safe use of Chainsaw Chain while using it.

It should be tightened and checked properly while using it.

Important points to note in chain saw adjustment

Tips on tightening chainsaw chain

Here, we shall provide in-depth highlights of how to maintain and preserve your Chainsaw for extended performance.

Operators of Chainsaws should always be watchful of the chains before switching-on the chainsaw.

The tension in the string should be checked before every use.

If the pressure is not ideal, then you can adjust it using the tension screw.

To increase the tension in the chain, you should turn the screw in a clockwise direction.

Ensure that the chain is not too tight, to avoid breakage.

In some cases where the chainsaw is too taut, the chain of the chainsaw can break, loose, unwrap, and jump out of the chain saw bar.

This is always very precarious as it can easily cause severe damage to the operator or other people around.

To reduce the tension in the chain and make it loose, you should turn the tension screw in an anti-clockwise direction.

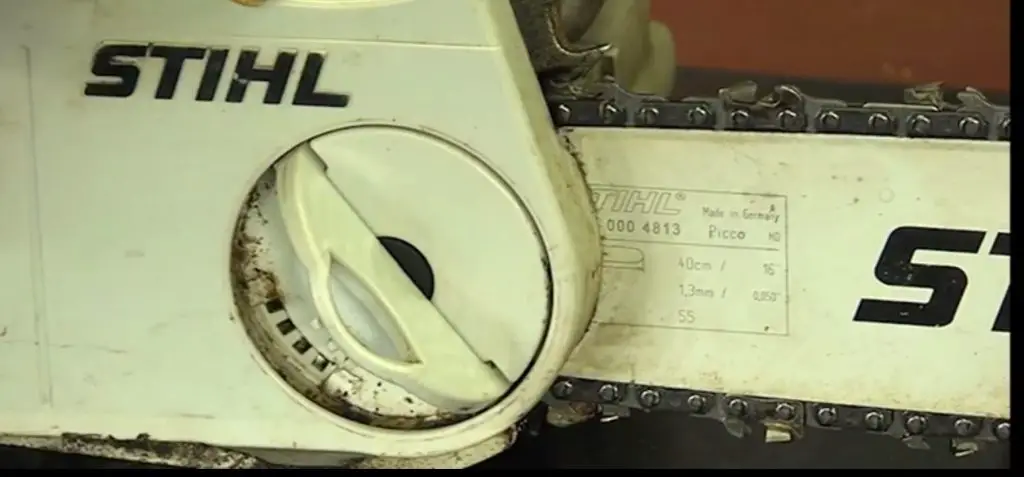

Cordless chainsaws offer a more easy tightening and loosening approach.

They come with the hand dial system for chain tension adjustment.

In this case, tension is adjusted by loosening the bar on the side panel of the guide bar.

This will give the room they need to be adjusted.

Anyway, the main problem with battery powered aka cordless chainsaw is its limited running time.

If you want to take a cordless chainsaw, make sure to select the chainsaw with long battery life and light weight.

A properly tensioned chainsaw chain should be just a little loose on the chainsaw guide bar, but the chain needs to be tight enough that you can’t pull the drive links out of the bar nose.

To adjust the chain tension loosen the bolts that fasten the motor base to mounting angles on both sides.

Tighten take up bolts until desired chain tension is reaches. Do not over tighten.

These are my most important recommendations.

Final Thought

The chainsaw should not be too taut.

You should strive to ensure that the tension is not much by allowing it to sag.

The chain saw would work perfectly when the sagging is faint and it would boost the efficiency of the guide bar.

There are several methods of checking whether the tension in the chain saw is ideal or not.

You can do so by reducing the level of the contact between the chain and the guide bar.

While doing so, you should be checking to see if the engagement in the drive links will still be there.

Lessening of the contact between the chain and the guide bar should be done such that it does not give room for the drive links to be disengaged from the guide bar