Chainsaw Bar Uneven Wear (Causes & Solution)

The issue of uneven bar wear in chainsaws can be remedied through several processes. First, by reversing the guide bar periodically, you can level out the wear. Second, if the guide bar rails are unequal, you can rectify this by grinding them with a flat file. Third, maintaining the chain carefully, such as keeping it sharp and correctly tensioned, can help prevent uneven bar wear. Lastly, it’s important to verify that your chainsaw’s oil pump is functional and that both the guide bar and chain are sufficiently lubricated.

Chainsaw bars can become unevenly worn over time, which can lead to decreased cutting efficiency and potential safety hazards.

Chainsaw bars that are not properly maintained can also cause excessive vibration, which can damage the saw blade and other parts of the chainsaw.

By regularly checking chainsaw bar wear and replacing them as needed, you can ensure that your chainsaw is performing at its best and stay safe while doing so.

Well, you may have been wondering how to do that, how to notice the signs of the worn-out bar in chainsaw, and how long can you use a worn-out bar, etc.

So below-answered are your queries in order to help you check out if the chainsaw bar is worn out or not:

how to fix Chainsaw Bar Uneven Wear issue

Flip over the guide bar: Periodically flipping over the guide bar can help even out the wear as much as possible.

Grind the guide bar rails: If the guide bar rails are uneven, you can try grinding them with a flat file to restore their evenness.

Proper chain maintenance: Ensure that you’re using a sharp chain, sharpening it correctly, and properly tensioning it to prevent uneven wear on the bar.

Check for proper lubrication: Make sure your chainsaw’s oil pump is working correctly and that the guide bar and chain are adequately lubricated.

Signs of the worn-out bar in chainsaw

As you keep using the tool, the tool tends to lose its power and strength over a while, which is quite normal.

Moreover, the tool begins to worn out eventually.

Well, here are a few signs for you in order to determine that it’s time for you to chain the chainsaw or replace the parts:

Poor performance during cutting

A sharp chainsaw that is present in the chain slices through the wood quickly.

In the case, if the teeth of the chain are quite sharp enough, the tool can easily pull it down to the wood, which further enables you to cut down the wood easily.

You are then able to spit out long branches, and create wafer-like chips when cutting woods, and more.

However, in the case, if you are finding difficulties and have to apply a lot of force in order to cut down any items using the chainsaw; it’s time for you to change it right away.

However, you will face a lot of friction when the cutting process is going on.

However, if the lubrication system of the chain’s tool is working correctly and the tension that is created is adjusted the right way then your chain is working fine.

In the case, if you are noticing any smoke that comes out while you are cutting trees, you must understand that the health of the tool is getting worse.

And hence, this is why it is causing a lot more friction than it is used to cause normally.

In such cases, you will have to repair or replace the tool depending on the condition it has.

Uneven cuts

A chainsaw chain can cut the wood or any such items in a clean and precise way.

The cutting process is much smoother in this case.

Moreover, it digs into the wood quite quickly but when you are facing difficulties while cutting the wood and are seeing uneven cuts, which are when you should replace and repair the tool.

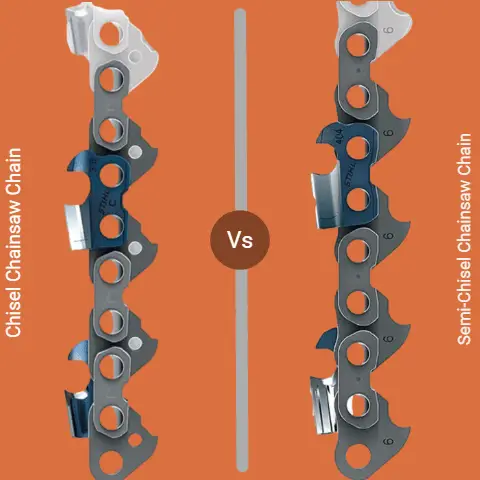

Uneven chain teeth length

One side of the chain teeth may be more worn than the other, indicating uneven wear on the bar

Uneven guide bar rails

The rails on the guide bar may be lower or thinner on one side, causing the chain to rotate at an angle

How to check outworn Chainsaw Bar?

Well, when we talk about the body of the chainsaw bars, it wears on the top side of the rails and the even surfaces inside the bar rails.

It’s quite easy for you to check out the rails from the topside as it is visible to the eyes, while the surfaces that lie inside the bar rails are quite challenging to check out.

You are required to pay undivided attention to the region that lies behind the nose of the bars.

Moreover, this is the specific location where the bar rails show most of the wear quite often.

Saw operators are responsible for doing limbing processes in order to notice the wear because this region does most of the work.

Also, you might also check out for other damages that are recommended by the experts.

In the case, if you see the nose region of the chainsaw bar looks good, then you must inspect the heels of the chainsaw rails.

If you notice any excessive wear, then you must have to repair that specific region.

It’s also advised that turning the bar around that helps you to see the profile of the heels.

In the case, if you see a narrow tail, then you must know that the bar is worn out.

Next, you might have to look at the groove of the bars and determine its depth.

In the case, if you see shallow rails then the bar heel is also worn out.

Similarly, you will have to examine all the parts of the bars carefully to determine how much it is worn out.

How long can you use a worn-out bar?

A very simple way of using a worn-out bar for an extended period of time is by rotating the rail of the bars.

And hence, whenever you are changing the chains that you must do at regular intervals, you are able to remove the chainsaw bar and then try to put them in an upside-down direction.

Well, you don’t have to get worried about the logo that’s painted on the chainsaw bar when it is turned upside down.

Moreover, rails have a greater chance to wear rapidly on the bottom part where the pressure of cutting is.

And hence, when you tend to rotate the bar, it spreads on both sides evenly.

Final Words

Apart from the above, a few measures of precaution can help in pushing the chainsaw’s life and not get worn out too quick.

These measures include regular maintenance, ensuring that the oil port is free of any blockage, tightening up the tension in the chain, and hence, reduce its time to get out of order too soon.