Skip Tooth Vs Ripping Chain (Explained)

A skip tooth chain is best for sawing large trees, cross-cutting sections of wood, and chainsaw milling, while a ripping chain is ideal for milling logs into planks and projects that require a smoother wood surface.

A chainsaw chain or the skip tooth chain is useful to cut large wood pieces and cross-cutting wood sections.

The gaps between the teeth drag reduce on the chain, thereby the debris produced is less.

The ripping chain is equally important as it cut across the wood grains.

Chainsaws are useful for all different jobs, and it means there are a variety of chains available.

If you figure out the best chainsaws, you should know what a skip tooth chain and ripping chain are.

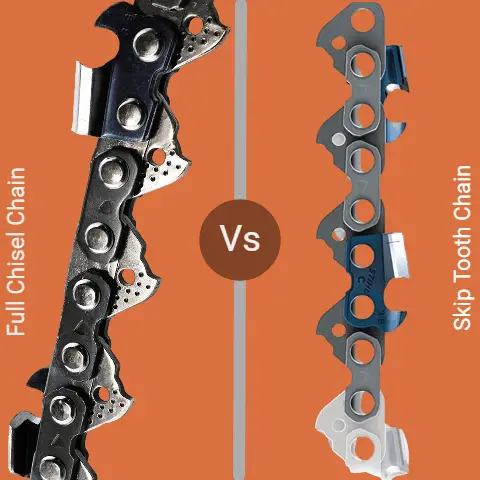

Here are a few differences between both types of chainsaws:

Skip tooth vs. ripping chain

A skip tooth chain has one tooth skipping or more removed. It is the reason to get the name to skip tooth.

On the other hand, a ripping chain is designed such that it cuts the wood grain.

The ripping chain is different from the regular chains as it cuts the wood grain.

The skip tooth chains use longer guide bars and lower-powered saws, to reduce the risk of kickback.

The ripping chain leaves a smoother finish than all other chains after it cuts the wood grain.

Advantages

Multiple advantages are with skip tooth chains.

They reduce the woodchips and debris amount produced from sawing.

The cutting teeth gaps scoop the debtors from between and allow the chain to release easily.

It means the skip tooth chains reduce the work largely as you need not keep stopping in between while working to clean the guide bar and the chain.

A ripping chain is appropriate if you want a smooth finish while milling to your log cuts.

There is an advantage to using a ripping chain over a regular chain.

You get a speed advantage in using the ripping chains.

The skip tooth chains use less power than per unit chain length, skip tooth requires less power to draw from the motor.

It allows for using longer bars and means to work more efficiently and longer.

The risk of kickback happening is less with a skip tooth chain.

The best part is that the skip tooth chain is suitable as beginner-friendly.

The cutter teeth do not become dull quickly and sharpening them all by yourself is easier.

It is a great practice to perform maintenance for a beginner on this type of chainsaw.

Ripping chains are micro-chisel or semi-chisel chains usually featuring a cutting angle of 10 degrees.

A regular ripping chain is different from a skip tooth chain.

A ripping chain may be in combination with a skip tooth chain style.

It is easy to remove from the chain every second tooth and to create a skip tooth chain of a ripping chain.

Best for

A skip tooth chain is best for the majority of saw jobs, such as sawing large trees, so requires a long bar.

The skip tooth chains offer a cut with a wider diameter.

The best part is the cutter teeth do not dull fast even on sawing a huge job.

Thus, the job is done well on time before the need for chainsaw maintenance becomes essential.

Skip tooth chains are best for wood cross-cutting sections.

Most jobs of sawing do not need to be precise and clean. It may be complete with a skip tooth chain.

A ripping chain is best to give a smoother finish on the surface cut than all other chains.

It is entirely different from skip tooth which offers a rough cutting finish.

A ripping chain is best used along the wood grain than on the veins or pores.

There are other options available in a ripping chain, such as the semi-chisel and full chisel.

A ripping chain is useful on shallow-angle cutters. This chain helps to mill and is used only in specific projects.

Not good for

Skip tooth chain is good for saw materials with a small or narrow diameter.

However, it requires a shorter bar featuring a chain as a full chisel chain, and it is good for such jobs.

But, a skip tooth chain vibrates and is painful on the wrists while holding the saw steadily and continuously.

Ripping chains are specific to cutting the wood grain, with the timber length.

Milling wood is its perfection, and it offers a clean finish.

However, it is unsuitable for the jobs that need to be done at speed.

The ripping chains take more time to give a clean surface and finer cut, and hence speed is a concern.

More features

Skip tooth chains decrease the flying debris produced and uses less power.

It is ideal to have long bars as the chainsaw power lasts longer.

The lesser power gives more control and promotes the safety of the chainsaw.

It also does not deal much with debris, so stopping frequently, and hindering work is off the bar.

Keep in mind that skip tooth chains through the chainsaw cause vibration, which increases with the bar length.

Yet, they are one of the best options to use with longer chainsaw bars.

Ripping chains feature two scoring and two clearing cutters, and along the chain, help cut through a smooth finish.

It offers a smoother finish cutting along the pores while milling the grain.

Its structure of semi-chisel ensures to keep it sharper for a longer time that there is a positive impact on productivity.

Bear in mind, that the chain design is resistant to damage, as you hit the debris in the wood.

It helps professionals in saving money, as they do not have to replace the chainsaw chains often.

Wrapping Up

Operating a skip tooth is easier, and the work is done speedily, but the finish is extremely rough.

However, they save time and do not need to stop repeatedly.

While a ripping chain works along the grain and the saw does not break or split wood fiber.

It offers a smooth finish and takes a wood shaving along the grain.

The ripping chain’s durable design ensures a smoother cut.

The vibration is more in skip tooth, while the ripping chain gives less vibration, meaning no or less kick-back.